■ Rotor profile

The disgusting work of Dr. Tang Yan, a global screw compressor design expert, adopts new achievements, and the rotor type linear energy has reached the international level. The combination of good processing performance and high-precision German Kapp Rotor Grinder creates high-precision rotor and realizes the excellent performance of screw host. The full spectrum screw host meets the national energy-saving standard, and some models reach the national energy efficiency level.

■ Features of screw main equipment

1、"Large rotor, low speed" design, direct drive of full spectrum screw host;

2、The compressor chamber of the main engine and the front bearing seat are designed in an integrated way, which is simpler and more compact in structure, with good machinability to ensure the reasonable clearance of each motion pair; the built-in design of the oil circuit of the main engine makes the connection between the main engine and the system more convenient and greatly reduces the fault source.

3、Bearing life ≥ 100000 hours;

4、The suction and exhaust orifices are optimized for different working conditions to ensure the high performance of the screw host under different working conditions;

5、High precision screw rotor realizes the unity of excellent performance and reliability;

6、With high efficiency, low noise and low vibration, the performance of screw host has reached the international level;

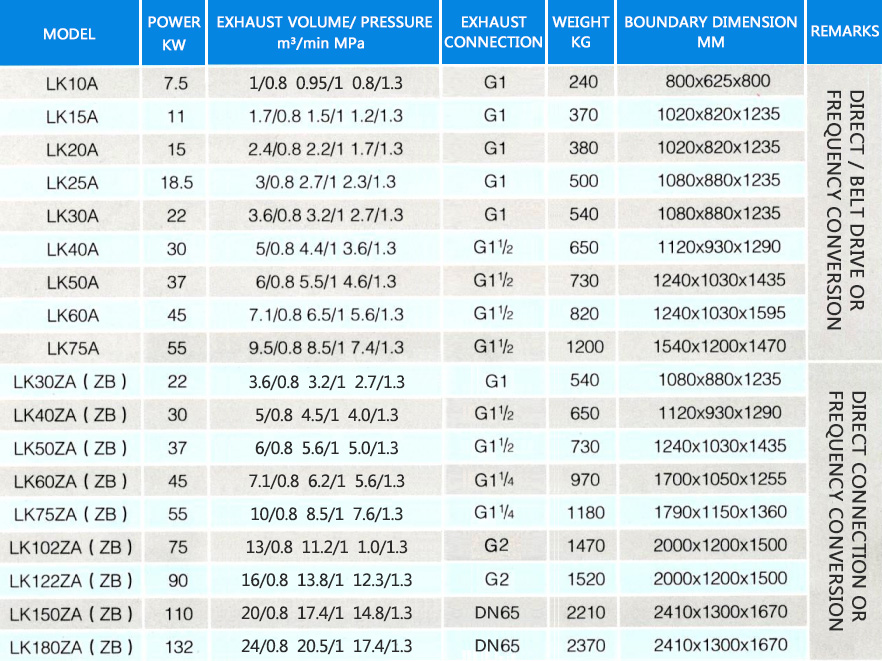

LK Screw Air Compressor

Note: A is belt connection, Za is direct connection, ZB is direct connection frequency conversion.

■ Processing and testing means of screw host

Metal processing adopts imported high-precision processing equipment, such as German Kapp Rotor Grinder, British horryd Rotor Grinder, British cylindrical and end face grinder, Japan Mitsui machining center, etc. the high-precision screw host parts ensure the performance and reliability of the compressor; The measurement level three coordinate measuring machine imported from Germany is used to detect the technician quality of screw host parts to ensure that the products meet the design requirements.

■ Each screw machine supports frequency conversion

The variable frequency function can be opened according to the user's requirements. The scope of supply of LK and LG series variable frequency Screw Compressors: power from 7.5kW to 355KW, flow from 1m3 / min to 60m m3 / min, discharge pressure from 0.5MPa to 2.5MPa, with various configurations of water-cooling, air cooling, belt drive and direct drive. PLC fully supports frequency conversion. Frequency conversion parameters can be displayed and set on PLC.

■ LK, LG series variable frequency compressor

The frequency converter is integrated in the air compressor to save space; there is no energy loss and peak current to achieve constant pressure; the vector frequency converter is convenient for constant torque output of the motor; low speed, no load start, high reliability; the frequency converter and PLC are integrated, easy to operate and humanized management.

■ Adopt well-known screw compressor host

The special rotor profile provides excellent performance for each type of head.

Strong axial and radial bearings ensure extremely long service life.

In key areas, triple shaft seal is used to eliminate leakage.

With precision hardened grinding O The wear-resistant shaft sleeve of type a seal ring has high maintainability.

Each product has the world's high level of performance and efficiency, and produces large exhaust with small motor power.

■ Human interface display and control system

The operation is very convenient and simple.

The operation state is clear at a glance.

If any abnormal factor occurs, Chinese prompts for maintenance or repair.

Equipment input interface is reserved to realize interlocking control and remote diagnosis control of multiple units.

The imported high-tech microcomputer controller has powerful fault diagnosis and protection functions

Phase loss protection: any phase or two phases of the three-phase power supply are disconnected, and the power supply is cut off automatically.

Phase sequence protection: when the phase sequence of three-phase power supply is wrong, it cannot be started.

Over temperature protection: when the exhaust temperature exceeds the set value, the power supply will be cut off automatically.

No load protection: no load for several minutes, automatic shutdown, and automatic start-up when gas is needed.

Automatic unloading: unload first, then stop the machine to avoid heavy start.

Air volume adjustment: automatically adjust the exhaust volume, saving consumption.

■ A complete set of imported gas volume control system

The positive and negative proportional valves feed back all the pressure signals to the servo cylinder and intake control valve.

The air inlet control valve implements 0-100 stepless regulation on the exhaust volume, so that the air supply is consistent with the air consumption, and the energy-saving effect is excellent.

The temperature control valve sets the opening and closing temperature, automatically adjusts the lubricating oil temperature, keeps the viscosity of the lubricating oil in a good state, ensures that the exhaust temperature is above the pressure dew point temperature, and prolongs the replacement cycle of the lubricating oil.

■ a complete set of imported gas volume control system

The positive and negative proportional valves feed back all the pressure signals to the servo cylinder and intake control valve.

The air inlet control valve implements 0-100 stepless regulation on the exhaust volume, so that the air supply is consistent with the air consumption, and the energy-saving effect is excellent.

The temperature control valve sets the opening and closing temperature, automatically adjusts the lubricating oil temperature, keeps the viscosity of the lubricating oil in a good state, ensures that the exhaust temperature is above the pressure dew point temperature, and prolongs the replacement cycle of the lubricating oil.

The minimum pressure valve ensures that the fuel injection pressure required for engine lubrication is maintained, reduces the air flow rate of the oil-gas separator, makes the effect of the oil-gas separator better, and has the function of check valve.

|

■ Inlet filter system

High efficiency oil gas separator, so that the oil content of exhaust gas is lower than 3ppm.

High efficiency oil filter can remove impurities in lubricating oil and provide clean lubricating oil for head rotor and bearing.

High efficiency air filter, filter the dust and impurities in the air, so that the head rotor, bearings and other damage free.

Accessory differential pressure sensor, when the filter is blocked and the front and rear differential pressure exceeds the set value, it will automatically alarm to remind you of maintenance or replacement.

|

|